College of Agricultural Engineering and Technology

In backdrop of the existing policy for agricultural development in Bihar, necessity was felt for intervention of engineering and technological aspects in agriculture and therefore, the Govt. of Bihar took decision to establish a College of Agricultural Engineering in the main campus of the then Rajendra Agricultural University, Pusa in the state of Bihar. College of Agricultural Engineering (CAE) was established on 7th December, 1983 under Rajendra Agricultural University for imparting education, conducting research followed by transfer of technologies to the farmers and entrepreneurs, and later rechristened as College of Agricultural Engineering and Technology (CAET) in 2022. CAET got accredited by National Agricultural Education Accreditation Board (NAEAB) w.e.f. 28th March 2022. The college, thus aims to support the agriculture of the State as well as country in wider prospective by way of intervention of engineering related technologies in production and post-production systems, so as to make the agriculture profitable and sustainable in long run.

VISION

To create a unique teaching-learning environment through technical education and scientific research in the discipline of agricultural engineering; to produce technical experts, researchers and entrepreneurs passionate to serve our farmers and industries.

MISSION

- To impart new knowledge among agricultural engineering graduates by engaging in rigor academic curriculum, innovative research and industrial training.

- To produce exemplary researchers and educators through quality education and cutting-edge research in postgraduate programmes.

- To identify the regional and national researchable issues for achieving sustainable food production by undertaking collaborative projects with academia and industry.

- To disseminate appropriate agricultural technologies to the farming communities and industries.

VALUES

- Research and teaching shall be carried out with honesty, maintain the highest standards of ethics.

- Accountable to all the stakeholders including students, faculties, staffs and alumni.

- Transparency shall be maintained among all academic and research activities.

DEPARTMENT AND TECHNOLOGY CENTRES

- Department of Farm Machinery and Power Engineering (FMPE)

- Department of Soil and Water Engineering (SWE)

- Department of Processing and Food Engineering (PFE)

- Department of Food Technology (FT)

- Centre of Excellence on Water Management (CoEWM)

- Farm Machinery Testing Centre (FMTC)

- Bamboo Training Centre (BTC)

College of Agricultural Engineering and Technology provides agricultural-based engineering education to produce quality engineer-scientists. The curriculum provides rich exposure to both theoretical and practical knowledge and simultaneously builds a temper for the life long process of learning and exploring.

ADMISSION

Admission to CAET is possible through entrance examination. At present, 100% admission in UG/PG/PhD degree programmes is done through ICAR – AIEEA. For admissions in Post graduate diploma in Agri-Warehouse Management, a proficiency test is being conducted followed by group discussions and for Certificate course, a common competitive examination is conducted followed by Viva.

DEGREE PROGRAMMES

| Programme | Discipline | Year of Start | Intake |

| Bachelor of Technology | Agricultural Engineering | 1983 | 44 |

| Food Technology | 2021 | 33 | |

| Master of Technology | Farm Machinery & Power Engg. | 1988 | 10 |

| Soil and Water Conservation Engineering | 10 | ||

| Processing and Food Engineering | 10 | ||

| Doctor of Philosophy | Farm Machinery & Power Engg. | 2020 | 05 |

| Soil and Water Conservation Engineering | 2019 | 05 | |

| Processing and Food Engineering | 2020 | 05 | |

| Postgraduate Diploma | Agri-Warehouse Management | 2021 | 25 |

| Certificate Course | Farm Mechanization Assistant | 2021 | 20 |

ACADEMIC SYSTEM

The college follows the semester system. An academic year comprises of two semester and runs from July through June next year. Generally, the 1st semester starts in the last week of July and ends in the 1st week of December; and the 2nd semester starts in the first week of January and ends in the 2nd week of May.

The Academic Schedule (Calendar of Academic Events) published by the Office of Registrar is followed. Academic Schedule is published well in advance before start of the semester.

SCHOLARSHIPS

1.Undergraduate Programmes

❖ University Fellowship: The students of the Bihar state will receive a stipend of Rs 2000/- per month up to 8th semesters.

❖ NTS Scholarship: For students outside the state of Bihar, NTS scholarship are provided by the ICAR.

❖ Book Grant will be reimbursed to the students on production of cash memo for purchase of textbooks and other reading materials recommended by the course instructor.

2. Post Graduate Programmes

i. M.Tech. Students

❖ University Fellowship: The students of the Bihar state will receive a stipend of Rs 3000/- per month.

❖ NTS Scholarship: For students coming through ICAR competition and are outside the state of Bihar, Rs 5000/- per month is provided to the students.

ii. Ph.D. Students

❖ University Fellowship: The students of the Ph.D. will receive a stipend of Rs 4500/- per month.

I. Research Projects in Operation

| S. N. | Title of Projects | Funding Agency | PI and Co-PI |

| All India Coordinated Research Project (AICRP) | |||

| 1. | AICRP on Farm Implements and Machinery

| ICAR New Delhi | Dr P. K. Pranav, |

| 2. | AICRP on Post Harvest Technology

| Dr Devendra Kumar | |

| 3. | AICRP on Irrigation Water Management

| Dr S. P. Gupta | |

| External Funded Project | |||

| 1. | Development of microcontroller based automatic depth control system for mounted implements | DST, New Delhi | Dr P. K. Pranav |

| 2. | Scaling up Climate Smart Agriculture (CSA) through Mainstreaming Climate Smart Villages (CSVs) in Bihar | ADMI, UIUC, USA | Dr Vishal Kumar, |

| Consultancy Project | |||

| 1. | Consultancy project on software validation | M&M Ltd. | Dr P. K. Pranav |

| 2. | Performance Evaluation of Rain-Pipe Irrigation under small & Marginal Farming System in Bihar | V K Pack Well Pvt. Ltd., Kanpur | Er I. B. Bhagat |

| University Funded Project | |||

| 1. | Development of real time soil Nitrogen (N), Phosphorus (P) and Potash (K) sensor | RPCAU, Pusa | Dr S. K. Patel |

| 2. | Development of packaging materials from maize cob | Dr S. K. Patel | |

| 3. | Development of refrigerated vegetable cart for small vegetable vendors | Dr S. K. Patel | |

| 4. | Mechanization of turmeric crop through development of planter and harvesting implements | Er Manoranjan Kumar | |

| 5. | Design and development of self-propelled automatic vegetable transplanter | Dr Jaya Sinha | |

| 6. | Development of tractor operated multi-crop seeder | Dr Subhash Chandra | |

| 7. | Development of planter and digger for Taro crop | Dr Subhash Chandra | |

| 8. | Development of Low Cost Storage Facility for Bulk Storage of Fruits and Vegetables | Dr Vishal Kumar | |

| 9. | Empowering Farmers towards sustainability through Innovative Irrigation and drainage options for Mokama Tal Area of Bihar. | Dr. Ravish Chandra | |

| 10. | Planning and Development of Water Positive Zone for Sustainable Aquifer Management | Dr. Ravish Chandra | |

II. Technology Released

1.Chulha for Grain Puffing Machine

The developed Chulha for grain puffing is fuel efficient, facilitates easy transportation, saves time, labour and money consumed in grain puffing operation.

|

2. Process technology for preparation of Ripe Bael Fruit Powder for Bael Sharbat

The process technology is economically viable, generate income and employment and gives healthy new product from bael. An invesment of Rs. 700 to 850 will be required to produce 1 kg of Bael fruit powder, this powder can be used to futher produce 200 glasses of Bael sharbat @ Rs. 20/glass in the local market in the off season

|  |  |

3. Ready To Use Bio- clarificant for Quality Jaggery Production

Okra stem, soybean seeds and fenugreek seeds mixtures were used for the preparation of Ready to Use (RTU) bio- clarificants for the production of quality jaggery. The optimized RTU clarificant had okra stem- 50 per cent, soybean seeds- 10 per cent and fenugreek seeds – 40 per cent which was added to the sugarcane juice @0.5 percent.

|

4. Osmo- freeze Dried Strawberry slices

The process technology for production of high-quality osmo freeze-dried strawberry slices was developed. The optimized process conditions (desirability = 0.692) were 50% sucrose concentration; 2 mm slice thickness and – 22 0C freeze drying operating temperature which resulted final moisture of 5.55%, colour 68.9, water activity 0.40, rehydration ratio 3.27 and overall acceptability 6.31.

|

5.Portable Corn Roaster-cum-boiler

A roaster-cum-boiler was developed operated on liquefied Petroleum Gas (LPG) as fuel source. The developed unit can roast 30 maize and can boil around 28 maize in an hour. The average heat utilization factor in full load condition was 0.254. An average thermal efficiency of 61.88% was obtained for the unit. The mean roasting efficiency of the developed corn cob roaster cum boiler was determined to be 95.07 per cent. Total cost of the functional prototype is Rs 20500.

|

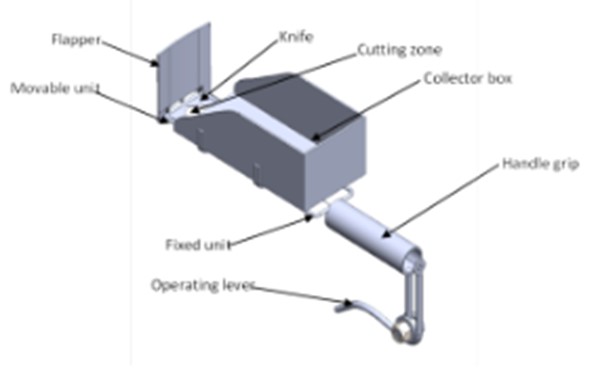

6. Manual Cabbage Harvesting Machine

The cabbage harvester comprises cutting, conveying and collecting system. The cutting is powered by human through lever, however, conveying is powered by battery. The machine saves about 28% time in comparison with traditional method and reduces human energy demands.

|  |

7. Hand Tool for Okra Harvesting

The tool is feasible for okra harvesting in terms of harvesting function, capacity and cost. It has added advantage of comfort and ease of operation which enhances the harvesting period of a worker. Enhances the shelf life of okra after harvest.

|  |

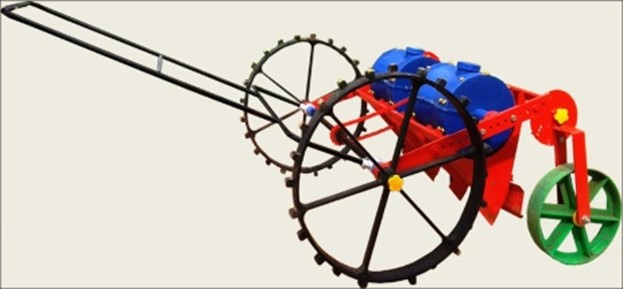

8. Rice-Wheat Seeder (manually operated)

Low cost & easy in operation. Suitable for direct seeding of paddy and line sowing of wheat. Increases the yield by 5-28% Saving of Rs.3500-4000 per acre in paddy.

|

9. Pigeon Pea Stalk

A conservative estimate suggests availability of about 7 lakh ton unused Arhar stalk. RPCAU found that the stalk can be used in manufacturing several artifacts and furniture like center table, pen holders, cutlery etc., and can be used in incense stick manufacturing.

Centre Table Leg Size 7cm*8cm*40cm Top space with Glass 122cm*46cm |

Dholchi Bottom 13.5cm*11.3cm Top 16.3cm*14.0cm |

Side Table Leg Size 10cm*10cm*46cm; Glass Radius 18cm |

Cutlery Items Spoon/ Chopstick/ Knife/ Fork |

III. Patent Granted: 01

- Self-propelled rotary power paddy weeder

- Patented (Patent no. 379307)

- Commercialized with BCS, India.

- Cost of weeding Rs.2500-1200/ha.

- Increases- Yield and Water use efficiency.

|

1.Skilled Training Program of Rural Youth

- Skill Training for “Services and Maintenance Technician-Farm Machinery” organized to aim at imparting skill-based training in repair and maintenance of farm machineries to rural youth to promote employment in rural areas.

|  |  |  |

- PFDC, SWE, CAET, RPCAU, Pusa, Samastipur has successfully organized one month (200 Hrs) Agriculture Skill Council of India (ASCI) training on Micro-Irrigation Technician.

|  |  |  |

- Farmers Training: SWE has been actively involved in farmers’ training. Till now 115 training have been conducted where 4500 farmers have been trained.

|  |

- Officers Training: Department also provides officers training. Total number of Officers training are 10 where approx. 300 officers are trained till now.

2.Technology and Machinery Demonstration Mela

Technology and Machinery Demonstration Mela under AICRP or various projects has been organized by the department periodically in various districts of Bihar. The aim of such technology mela is to disseminate the technologies among the farmers and agricultural innovators. Students get a chance to interact with various farmers, manufacturers and entrepreneurs. Farmers actively participate in such mela and manufacturers display their latest agricultural technologies.

|  |

3. Industry Academeia Meet

FMPE organizes Industry -academia in hybrid mode to have sound and insightful discussion on farm mechanization in India with agricultural engineers from academia, government policy makers and entrepreneur.

|  |

4. Front line demonstrations

Front Line demonstrations (FLDs) to have direct interface between researcher and farmers for the planning, execution and monitoring of the demonstrations of the technologies developed by them and get direct feedback from the farmers’ field.

|  |

5. National campaign on Farm Mechanization

National campaign on Farm Mechanization organised by AICRP -FIM by department of FMPE. Under this campaigning various activities like Kisan Chaupal,field day, quiz,slogan and song competition among students with theme farm mechanization were carried out to create awareness and importance of farm mechanization.

|  |

6. Kisan Mela: SWE actively participate in Kisan mela organized by the RPCAU

More than 35000 farmers have been given knowhow about Agricultural Engineering related technologies such as Farm machines, post-harvest & food processing and Micro Irrigation System (MIS) and Protected Cultivation.

|  |  |  |

|  |  |

All the departments are well equipped with modern laboratories. In addition the college has computer center with free access to internet, Students workshop, Library, GIS Lab. and a Training Cell.

| Computer Laboratory Well equipped computer laboratory with Latest Desktop Computers (Windows 10) and internet access are available for the students. |

| Farm Machinery Laboratory The Farm Machinery laboratory of the college is well equipped with modern energy-efficient farm machines like combine harvester, reapers, reaper binder, bed planting machine, rice-transplanter, drum seeder, Zero till drill, Straw harvester and all kinds of machines required for different farm operations. |

| Farm Power Lab The lab has facility for exposing the students to tractors, engines and their systems. The lab contains cut sections and models for various tractors and engine and their system such as crank arrangement, valve system, lubrication system, fuel system, gear system, hydraulic system etc. |

| Energy Park An Energy Park, in collaboration with the Ministry of New Energy sources, Govt. of India has been established at the college with the objectives to demonstrate and provide technical know-how to the local people and students about renewable energy gadgets. |

| Material Testing Lab This lab is well equipped with equipment like Universal Testing Machine, Fatigue, Impact, Torsion & Hardness testing machines to evaluate the strength & properties of different materials. |

| Soil Mechanics Lab Soil mechanics lab is one of the oldest lab of the college. This lab is essential as soil possess a variety of physical properties most of which are not constant. Soil mechanics lab is well equipped with all equipments required for identification and classification of soils. |

| Theory of Machines Lab The lab is equipped with working models of Gyroscope, Governors, Creep Testing, Gear Train, Vibration apparatus, Cam Apparatus etc. |

| Processing and Food Engineering Lab The Processing and food Engineering laboratory is well equipped with various kinds of modern equipments for the training of UG and PG students. Some of the equipments are Hunter Colour Lab, Textural Analyzer, Fruit Grader etc. |

| Agro-Processing Center It is equipped with different Agro-Processing machines/equipment for teaching, research and trainging/demonstration purpose like Mini Dal Mill with precleaner/grader, seed processing machines, papad making machine set, Oil expeller, Maize sheller etc. |

| Agricultural Product Processing Lab This lab is equipped with modern equipment/machines like Twin screw food extruder, spray dryer, litchi peeling machine, STR dryer, Turmeric polisher etc. |

| AICRP on PHE Lab Equipments/machines purchased under AICRP on PHET have been placed in this laboratory. |

| Irrigation Laboratory A laboratory with models of almost all the irrigation, drainage, sewage disposal structures is available which provides a means for effective training of the students. |

| Hydraulics Lab It is one of the important labs for UG and PG practicals. This lab is well equipped with a number of experimental setups for understanding the theory of hydraulics. |

| Wells and Pumps Lab This laboratory is one of the oldest lab of the college. Different parts of pumps and cut models of different pumps are displayed for practicals. |

More than 426 students have been honoured with B. Tech. degree and about 50 students have been awarded M.Tech. degrees in Agricultural Engineering by this college. Our students have made history in several fields. Most of our alumni are well placed in government as well as private sector organizations within India and abroad.

The students of this college are getting high ranks in all India level competitive examinations like GATE, IIM, IRMA, ICAR-JRF, IFS & leading financial institutions and Banks. Many times the students have secured 1st rank on all India basis in GATE.

The students of this college are holding the flag of the college up and high in several institutions. Some of them are :

- Various top rated universities of USA, Japan, Germany, Thailand & other countries.

- Indian Institutes of Technology

- Indian Institutes of Management

- Indian Institute of Forest Management, Bhopal

- Indian Rural Management Institute, Anand

- Indian Agricultural Research Institute, New Delhi

- State Agricultural Universities

Placement

On campus interviews are arranged as far as possible for the final year graduating students. The students graduating from this college are holding responsible positions in academics, manufacturing concerns, government organizations, public sector undertakings, NGOs and other agro related industries.

The college has highly qualified and well-versed faculty (most of them are from top-rated institutions of the country) in all the disciplines. A balanced mix of academicians & professionals constitutes to excellence and character of this institute.

| S. N. | Name | Position | Contact No. | |

|---|---|---|---|---|

| Dr. Ambrish Kumar, Ph.D. | Dean | 6287797112 | dean.cae@rpcau.ac.in | |

| Department of Soil & Water Engineering | ||||

| 1 | Dr. S. K. Jain | Professor & Head | 6287797202 | skjain@rpcau.ac.in |

| 2 | Dr. Ram Suresh | Professor | 9934832677 | rsuresh@rpcau.ac.in |

| 3 | Dr. Ravish Chandra | Associate Professor | 9431784140 | ravish@rpcau.ac.in |

| 4 | Dr. Ram Kumar Sahu | Assistant Professor | 7782019951 | rksahu@rpcau.ac.in |

| 5 | Er. Sanjay Kumar Nirala | Assistant Professor | 9931141220 | sknirala@rpcau.ac.in |

| 6 | Er. Sudarshan Prasad | Assistant Professor | 9123475773 | sudarshan@rpcau.ac.in |

| 7 | Er. I. B. Bhagat | Assistant Professor | 9471644828 | ibbhagat@rpcau.ac.in |

| Department of Farm Machinery & Power Engg. | ||||

| 1 | Dr. P. K. Pranav | Associate Professor & Head | 6287797205 | pkpranav@rpcau.ac.in |

| 2 | Dr. S. K. Patel | Associate Professor | 9724206107 | skpatel@rpcau.ac.in |

| 3 | Er. Kranti Kumar | Associate Professor | 9934296190 | kranti@rpcau.ac.in |

| 4 | Er. Subhash Chandra | Assistant Professor | 9431897510 | subhashchandra@rpcau.ac.in |

| 5 | Er. Manoranjan Kumar | Assistant Professor | 9431041987 | manoranjan.cae@rpcau.ac.in |

| 6 | Er. Sanjay Kumar | Assistant Professor | 6202511890 | sanjaykumar@rpcau.ac.in |

| 7 | Er. Shailesh Kumar | Assistant Professor | 8210973008 | shailesh.kumar@rpcau.ac.in |

| 8 | Er. Manoj Kumar | Assistant Professor | 6200986743 | er.manojfmpe@www.rpcau.ac.in |

| 9 | Er. Jaya Sinha | Assistant Professor | 6206047381 | jaya.sinha@rpcau.ac.in |

| Department of Processing & Food Engg. | ||||

| 1 | Dr. Mukesh Shrivastava | Professor & Head | 6203132402 | dr.mukesh@rpcau.ac.in |

| 2 | Dr. (Mrs.) P.D. Sharma | Professor | 6203234473 | dr.pratibha@rpcau.ac.in |

| 3 | Dr. Devendra Kumar | Professor | 9470832654 | devendra.kumar@rpcau.ac.in |

| 4 | Er. Vishal Kumar | Assistant Professor | 8709635031 | vishal.kumar@rpcau.ac.in |

| 5 | Er. Dinesh Rajak | Assistant Professor | 8986038207 | dinesh.cae@rpcau.ac.in |

Besides above faculty members, teachers of Basic Sciences & Agriculture Science also contribute to enrich the quality of teaching.